In the mid 1850's, a series of experiments were undertaken at Harper's Ferry and Springfield Armory to determine an optimal projectile for rifled muskets. The “elongated ball” design was the prime candidate, moving away from the simple round balls commonly used previously. Consideration was given to bullets which would be expanded during loading by action of ramming the bullet into place, as well as self-expanding bullets which deformed on firing, with the hot expanding gasses of the charge driving a cup, plug, or similar object into a hollow in the back of the bullet. Eventually, bullets obturated during loading were rejected due to difficulty in cleaning arms with the deformation mechanisms in their breeches, and the inconsistent deformation of the bullets when rammed by soldiers. “Plugged” bullets were found troublesome in that sometimes the plugs were blown completely through the bullet on firing and other times the plugs fell away from the bullet in flight and were considered hazardous when firing over friendly troops.

Bullets Tested in 1854

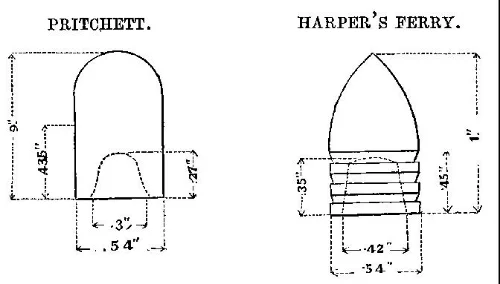

Eventually, James H. Burton, Master Armourer at the Harper's Ferry Arsenal, hit upon the idea of eliminating the cup or plug from the hollow-based bullets altogether, relying instead on the pressure of the expanding gasses from the charge to act against the inside walls of the bullet, thus expanding it. This design went through a few iterations in shape and size until finally the right combination was hit upon that provided a reliable projectile able to operate well out to 450 yards. In 1854 Burton's expanding ball was tested against the English Pritchett style of projectile, where Burton's bullet was pronounced to be the superior choice.

This resulted in another round of testing various calibers of the Burton expanding ball design at Springfield Armory in 1855. Tests were conducted using rifled (altered) .69 caliber muskets, .54 caliber rifled muskets, and .6 caliber bullets, which ultimately would be come the standard .58 caliber expanding ball bullet. The testing proved the design, and instructions were issued in July of 1855 to alter .69 caliber smoothbore muskets to be rifled to utilize the new expanding ball of that size, to alter 1841 .54 caliber rifles to .58 caliber, and to order new .58 caliber rifles and rifled-muskets (and pistols).

Bullets Chosen in 1855

These bullets had three cannelures, or grooves, which were filled with melted grease composed of one part beeswax to three parts tallow. It was specifically noted that care should be taken that no grease should be left on the base of the bullet, as it would bear against the paper barrier between the bullet and the powder charge in the cartridge and could wick through and injure the powder.

Like the round ball ammunition that preceded them, expanding ball bullets were put up in paper cartridges which encapsulated the powder and the bullet. Importantly, unlike the British Enfield cartridge, where the paper part of the cartridge was an integral part of the ammunition loaded into the muzzle, the US Expanding Ball cartridge was simply a container for the powder and bullet, each to be removed from the cartridge and used alone. This design was considered superior to the British Enfield style of cartridge, as it eliminated what were considered defects in the British design – the reversed position of the bullet in the cartridge and the use of the paper body of the cartridge as a paper patch for the bullet.

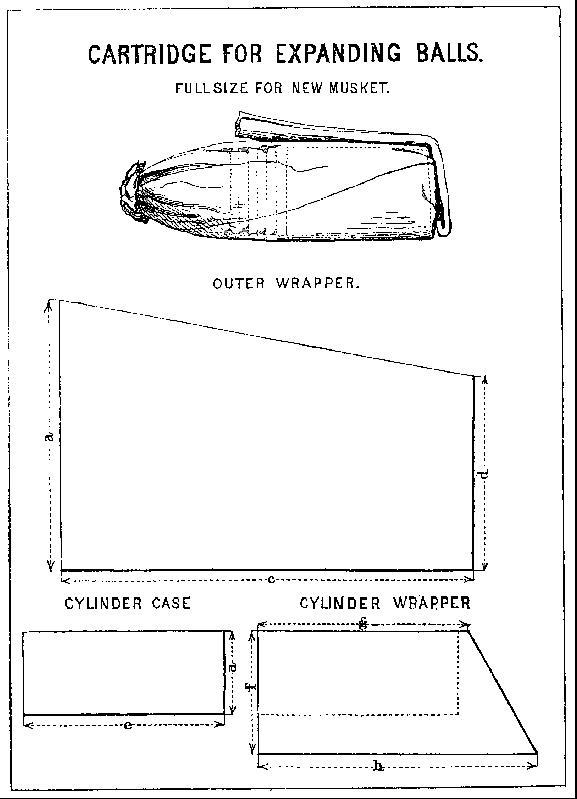

The initial design of the expanding ball cartridge was more complicated than that which it would evolve into after the start of the Civil War. It utilized 3 separate pieces of paper, made from 2 different kinds of paper: a thicker “rocket paper” used to make the portion of the cartridge that contained the powder, known as the powder cylinder, and a thinner paper which was used to encase the powder cylinder and the outer wrapper of the entire cartridge which contained the powder cylinder and the bullet. This design offered some inherent advantages. The thicker powder cylinder provided good protection for the cartridge, keeping it rigid. It made a natural stress point at the junction between the bottom of the powder cylinder and the base of the bullet, easing the breaking open of the cartridge to free the bullet, and it resulted in the “tail” of the cartridge being a single layer of paper which eased its tearing off to expose the powder charge and allow it to be poured out of the cartridge. Additionally, when the tail is torn off, the exposed stiff powder cylinder helps keep the mouth of the cartridge open so that the powder can pour freely out of the cartridge and down the muzzle of the firearm.

The instructions for making the US 1855 Expanding Ball cartridge are reproduced here from Reports of Experiments with Small Arms for the Military Service, published by the United States War Department in 1856, as follows:

“The diameters of the round sticks on which the powder cases are formed should be .69 inch for the old, and .58 inch for the new calibre. This will make the exterior diameter of the case somewhat larger than the ball, and will prevent the outer wrapper from binding around its base when the cartridge is broken.

The outer wrapper should not be made of too strong paper: that prescribed in the Ordnance Manual for blank cartridges, and designated as No 3, will answer a better purpose for these cartridges than that designated as No. 1. The cylinder case should be made of stiff rocket paper, No. 4; and its wrapper may be made of paper No. 1, 2, or 3.

Before enveloping the balls in the cartridges, their cylindrical part should be covered with a melted composition of one part beeswax and three parts tallow. It should be applied hot, in which case the superfluous part would run off; care should be taken to remove all of the grease from the bottom of the ball, lest by coming in contact with the bottom of the case, it penetrate the paper and injure the powder.

The balls being thus prepared, and the grease allowed to cool, the cartridges are made up as follows, viz: place the rectangular piece of rocket paper, called the cylinder case, on the trapezoidal piece, called the cylinder wrapper, as shown by the broken lines of the plate, and roll them tightly around the former stick, allowing a portion of the wrapper to project beyond both case and stick. Close the end of the case by folding in this projecting part of the wrapper. To prevent the powder form sifting through the bottom, paste the folds, and press them on to the end of the stick, which is made slightly concave to give the bottom form of greater strength and stiffness.

After the paste is allowed to dry, the former stick is inserted in the case, and laid upon the outer wrapper (the oblique edge form the operative, and the longer vertical edge towards his left hand) and snugly rolled up. The ball is then inserted in the open end of the cartridge, the base resting upon the cylinder case, the paper neatly choaked around the point of the ball, and fastened by two half hitches of cartridge thread.

The former stick is then withdrawn, the powder is poured into the case, and the mouth of the cartridge is “pinched” or folded in the usual way.

To use this cartridge, tear the fold and pour out the powder; then seize the ball end firmly between the thumb and fore finger of the right hand, and strike the cylinder a smart blow across the muzzle of the piece. This breaks the cartridge and exposes the bottom of the ball; a slight pressure of the thumb and fore finger forces the ball into the bore clear of all cartridge paper. In striking the cartridge the cylinder should be held square across, or at right angles to the muzzle; otherwise, a blow given in an oblique direction would only bend the cartridge without rupturing it.

Cartridges constructed on these principles present a neat and convenient form for carrying the power and ball attached to each other, and they obviate two important defects of the elongated ball catridge commonly in use, viz: the reversed position of the ball in the cartridge, and the use of the paper wrapper as a patch. So far as they have been tried in the hands of the troops, they have been found to answer a good purpose.”

Wrapper Dimensions for 1855 Cartridge

Sources:

Round Ball to Rimfire, Part 1, Dean S. Thomas, 1997

Experiments with Small Arms for the Military Service, United States War Department, 185

Steve Sheldon has been in the N-SSA since 2012. He has been an avid shooter all his life and got into black powder after buying a British Enfield musket for Christmas in 2011. Doing Google searches about it after the fact led him to the N-SSA and to seek out the Deep South folks at a skirmish in Birmingham, Alabama. He shoots with the 4th Louisiana Volunteer Infantry and lives in Huntsville, Alabama, with his wife and two kids. He shoots Musket, Carbine, and Revolver, and just picked up Smootbore this past year. He hopes to be able to buy one of those fancy breech loaders one day as his arm gets tired trying to keep up with the rest of the team! re